Enclosed Roller-Belt Conveyors — A Superior Conveying Solution

BROCK® Enclosed Roller-Belt Conveyor Systems offer you the added-value quality features and the rugged design needed for gentle, efficient and dependable conveyor operation. These conveyors are designed for commercial and mill operations including:

- Reclaim conveyor

- Fill conveyor

- Transport conveyor

- Multiple commodities

More

BROCK® Enclosed Roller-Belt Conveyor Systems feature galvanized steel construction. Inlets and head discharges are fully lined with urethane for long life. Self-aligning, heavy-duty bearings mount on the outside of the conveyor’s housing for easy maintenance and monitoring, longevity and safety.

Conveyors are computer-matched to the motor drive and gear reducers needed for efficient, energy-saving operation, and they are able to start under full load. Smoother belt operation is provided by Brock’s unique, heavy-duty idler pulley designs.

They offer clean, dependable, long-lasting operation with the conveyor’s totally enclosed dust- and weather-tight design. Additionally, the efficient, self-cleaning tail section recaptures grain spilled from belt.

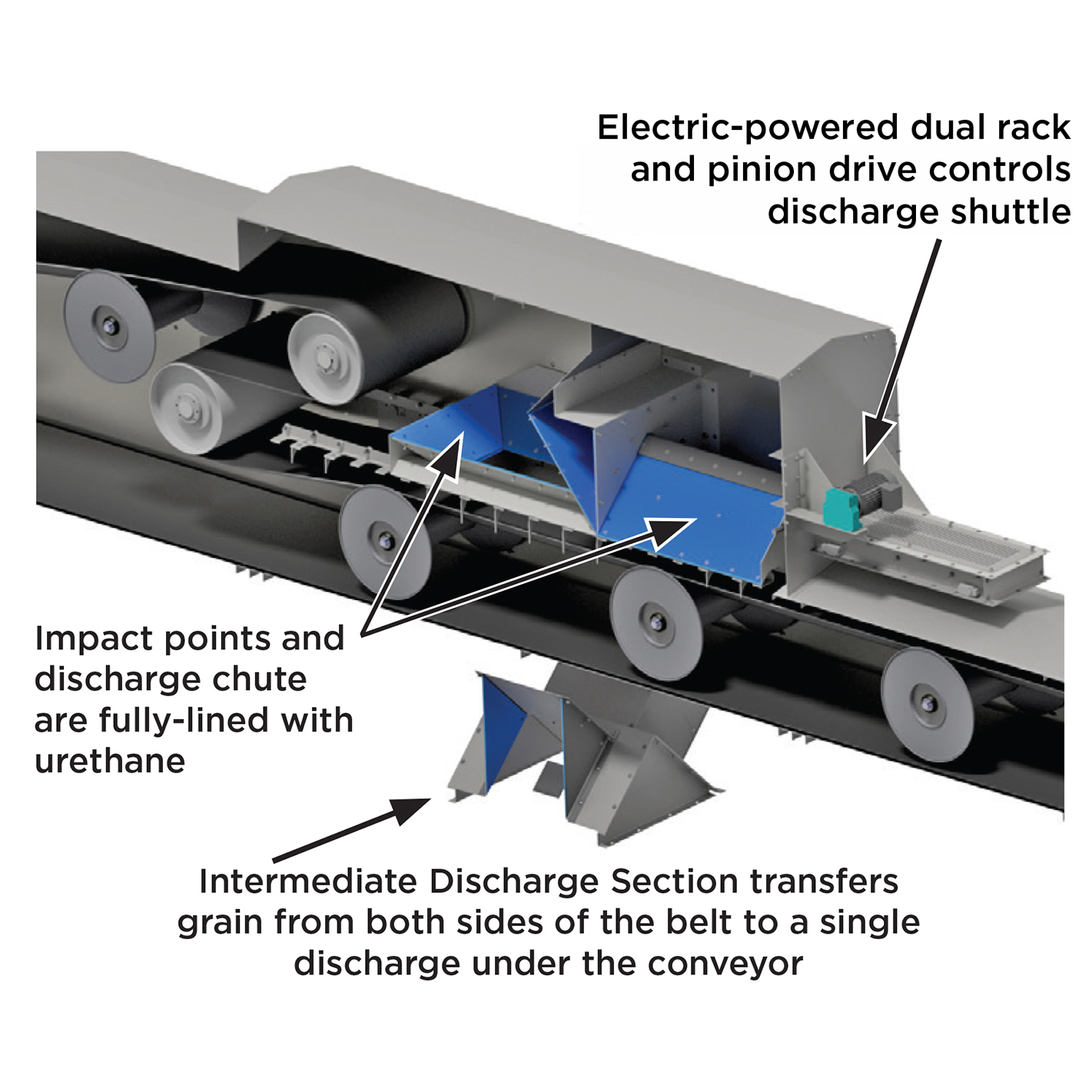

This is a streamlined roller-belt conveyor that offers versatility and helps you to efficiently handle various grains. With the BROCK® Intermediate Discharge Unit, one enclosed roller-belt conveyor system can have multiple discharge points to easily service many bins! It is grain conveying at its best. Here is why:

- The BROCK Intermediate Discharge Unit is easy to install and service.

- Works with BROCK Enclosed Roller-Belt Conveyors in belt widths from 26 to 54 inches (650 to 1350 mm) and speeds from 400 to 700 feet per minute (2.0 to 3.6 meters per second).

- Retrofits to existing BROCK Roller-Belt Conveyor Systems.

- No moving parts come in contact with the belt.

- Impact points and discharge chute are fully lined with wear-resistant urethane.

- The Intermediate Discharge Section transfers grain from both sides of the belt to a single discharge under the conveyor.

- An electric-powered dual rack and pinion drive controls the discharge shuttle.

- Gradual inclines and sharp upbends

- Gravity belt take-ups

- Conveyor sensor options

- Conveyor belting options

- Removable panels to facilitate belt splicing

- Removable panels for return belt cleanout

- Inspection doors for safe visual check of belt alignment

- Intermediate sidewall inspection doors

- Floor supports and hanger brackets

- Self-cleaning tail pulley design

- Conveyor skirting

- Easy removal of conveyor trough section lids

- Hinged tail pulley cover for easy maintenance access

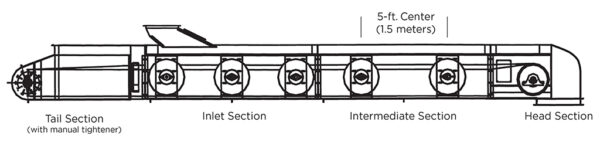

- Factory-assembled in 20-foot (6-meter) sections for faster field installation

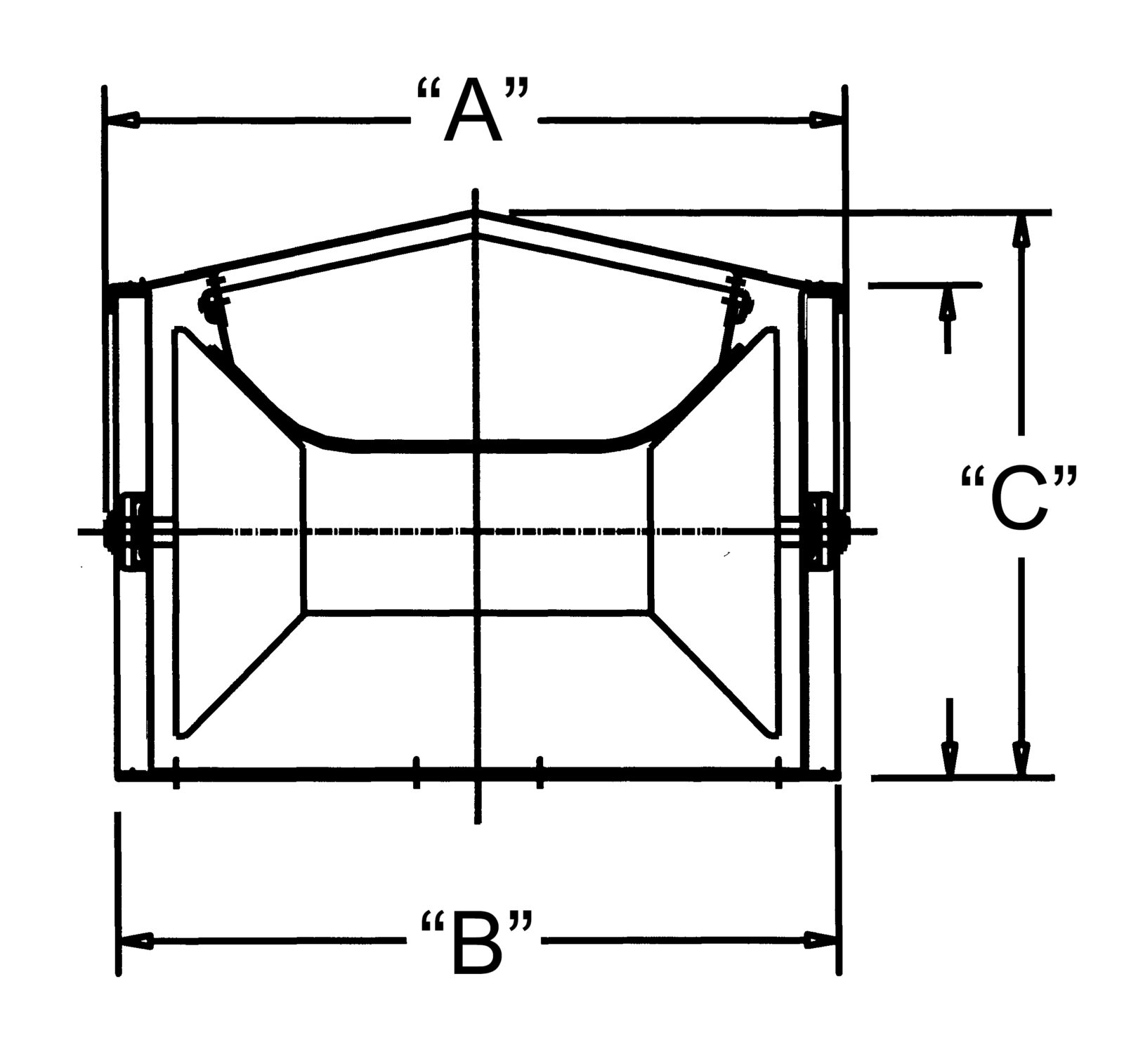

A smooth-operating conveyor system happens only by design. For an enclosed roller-belt conveyor that provides longer bearing life, smoother operation and minimizes vibrations, Brock incorporated the following design features:

• Full-length shaft with positive- locking tapered bushings on idler pulleys provide uniform weight balance.

• Pulley and bearing shaft is 1-1/4-inch (32 mm) diameter for less deflection and longer conveyor bearing life.

• Idler pulleys in the conveyor’s standard intermediate 10-foot (3-meter) sections are mounted on 5-foot (1.5-meter) centers for efficient belt operation and less spillage between carrying and return belts. Other intermediate section lengths are available.

• Conveyor loading section features pulleys on 3-foot (914-mm) centers for uniform belt loading and support at load points.

• All idler pulleys are adjustable for belt training.

Enclosed Roller-Belt Conveyor Capacities

| Model | Units | Belt Speed - Feet Per Minute (Meters Per Second) | ||||||

|---|---|---|---|---|---|---|---|---|

| 400 ft/min (2.0 m/sec) | 450 ft/min (2.3 m/sec) | 500 ft/min (2.5 m/sec) | 550 ft/min (2.8 m/sec) | 600 ft/min (3.0 m/sec) | 650 ft/min (3.3 m/sec) | 700 ft/min (3.6 m/sec) |

||

| 26 | Bu/Hr (MT/Hr) | 10,300 (261) | 11,600 (294) | 12,900 (327) | 14,100 (359) | 16,400 (392) | 16,700 (425) | 18,000 (457) |

| 30 | Bu/Hr (MT/Hr) | 13,100 (333) | 14,800 (376) | 16,400 (417) | 18,100 (459) | 19,700 (501) | 21,400 (542) | 23,000 (584) |

| 36 | Bu/Hr (MT/Hr) | 17,100 (435) | 19,300 (490) | 21,400 (544) | 23,600 (599) | 25,700 (653) | 27,900 (708) | 30,000 (762) |

| 42 | Bu/Hr (MT/Hr) | 22,900 (581) | 25,700 (653) | 28,600 (726) | 31,400 (798) | 34,300 (871) | 37,100 (943) | 40,000 (1,016) |

| 48 | Bu/Hr (MT/Hr) | 27,600 (701) | 31,100 (789) | 34,500 (876) | 38,000 (964) | 41,400 (1,052) | 44,900 (1,139) | 48,300 (1,227) |

| 54 | Bu/Hr (MT/Hr) | 33,000 (838) | 37,200 (944) | 41,300 (1,049) | 45,400 (1,154) | 49,600 (1,259) | 53,700 (1,364) | 57,800 (1,468) |

Brock Solid Grain Handling BR-2277/202203 (888.88kB)

Brock Solid Grain Handling BR-2277/202203 (888.88kB) Brock Solid Enclosed Roller-Belt Conveyors BR-2312-202201 (672.56kB)

Brock Solid Enclosed Roller-Belt Conveyors BR-2312-202201 (672.56kB)