Dependable Drag Conveyors for Steeper Inclines

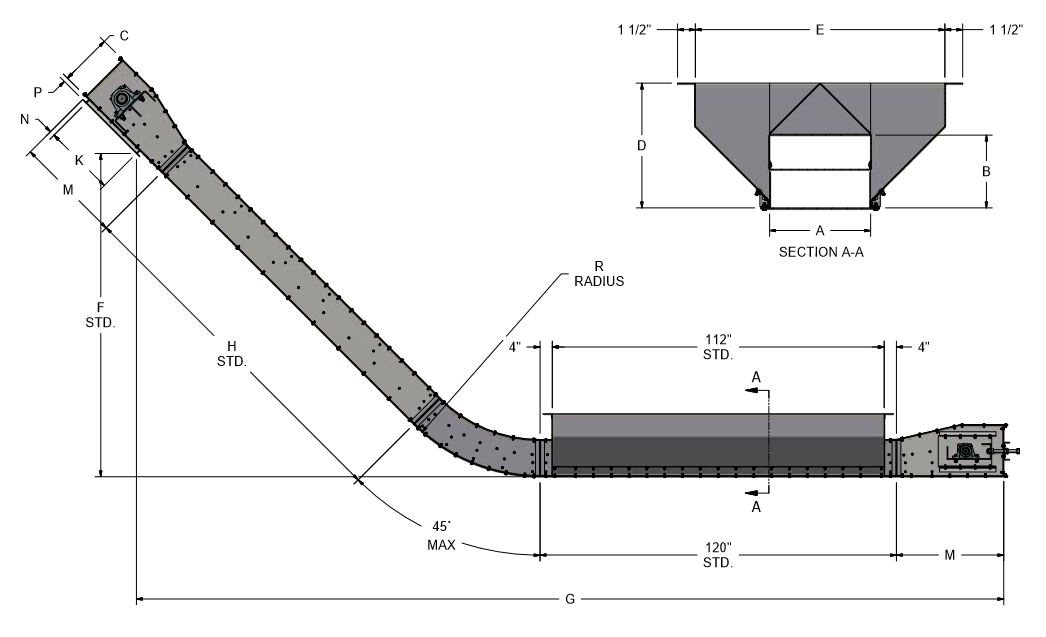

BROCK SOLID® Curved Incline Conveyors are used when applications require more than the normal 10° maximum incline of a BROCK Easy-Flo or Sur-Flo Conveyor.

From whole grains to feed to fertilizer, Brock helps you get product where it needs to go. Brock’s conveyors are built for performance and endurance under the most demanding of conditions. They offer key features that extend life and increase productivity.

More

- Standard inlet (may be choke fed in some cases).

- Manual, electric, hydraulic or pneumatic slide gates available.

- All steel chain is engineered and designed for extended life as well as maximum working loads. Chain is either welded steel or roller bushed.

- Bearing support mount constructed of 1/4-inch (6.4-mm) plate and welded in place for maximum strength.

- Flight attachments are constructed of heavy plate steel and welded to chain.

- All head, tail, and trough sections are shipped fully assembled for fast field installation.

- Internal return pan is bolted and replaceable.

- Bottom splice plates for accurate alignment thru 17-inch (432-mm) tall models. Bolted bottom overlaps on 20-inch (508-mm) tall and larger models.

- Bolted bottom trough section for ease of maintenance and replacement.

- Flame cut steel, hardened rim C-hub sprocket. Split style is optional.

- Tension type screw take-up for more durable service.

- Turned, ground, and polished shafts constructed of #1045 steel.

- Abrasion-resistant bottoms, return pans and side liners are available in a variety of thicknesses.

- Curved and close tolerance tail sections are optional.

- Paddles at chain splice are different color for easy identification during maintenance.

- Flights are a more robust 1/2-inch (12.7-mm) minimum flight thickness.

- All chain is shipped preassembled with flights attached.

- Bolted abrasion resistant steel side liner.

Curved Incline Conveyor Capacities*

| Size W x H | Capacity* | ||||

|---|---|---|---|---|---|

| (Metric) | Bushels per Hour | Cu ft per Hour | Tons per Hour | Chain Speed | RPM |

| 9 x 9 in. (229 x 235 mm) | 500 bph | 625 cu ft/hr (17.70 m3/hr) | 15 tph (14 mtph) | 46 ft/min (0.23 m/sec) | 21 |

| 1,000 bph | 1,250 cu ft/hr (35.40 m3/hr) | 30 tph (27 mtph) | 93 ft/min (0.47 m/sec) | 42 | |

| 1,500 bph | 1,875 cu ft/hr (53.09 m3/hr) | 45 tph (41 mtph) | 139 ft/min (0.71 m/sec) | 63 | |

| 2,000 bph | 2,500 cu ft/hr (70.79 m3/hr) | 60 tph (54 mtph) | 186 ft/min (0.94 m/sec) | 84 | |

| 12 x 9 in. (305 x 235 mm) | 1,000 bph | 1,250 cu ft/hr (35.40 m3/hr) | 30 tph (27 mtph) | 71 ft/min (0.36 m/sec) | 32 |

| 1,500 bph | 1,875 cu ft/hr (53.09 m3/hr) | 45 tph (41 mtph) | 104 ft/min (0.53 m/sec) | 47 | |

| 2,000 bph | 2,500 cu ft/hr (70.79 m3/hr) | 60 tph (54 mtph) | 139 ft/min (0.71 m/sec) | 63 | |

| 2,500 bph | 3,125 cu ft/hr (88.49 m3/hr) | 75 tph (68 mtph) | 175 ft/min (0.89 m/sec) | 79 | |

| 12 x 12 in. (305 x 311 mm) | 2,000 bph | 2,500 cu ft/hr (70.79 m3/hr) | 60 tph (54 mtph) | 101 ft/min (0.51 m/sec) | 33 |

| 2,500 bph | 3,125 cu ft/hr (88.49 m3/hr) | 75 tph (68 mtph) | 126 ft/min (0.64 m/sec) | 41 | |

| 3,000 bph | 3,750 cu ft/hr (106.19 m3/hr) | 90 tph (82 mtph) | 150 ft/min (0.76 m/sec) | 49 | |

| 3,500 bph | 4,375 cu ft/hr (123.89 m3/hr) | 105 tph (95 mtph) | 175 ft/min (0.89 m/sec) | 57 | |

| 17 x 12 in. (432 x 311 mm) | 3,000 bph | 3,750 cu ft/hr (106.19 m3/hr) | 90 tph (82 mtph) | 107 ft/min (0.54 m/sec) | 35 |

| 3,500 bph | 4,375 cu ft/hr (123.89 m3/hr) | 105 tph (95 mtph) | 122 ft/min (0.62 m/sec) | 40 | |

| 4,000 bph | 5,000 cu ft/hr (141.58 m3/hr) | 120 tph (109 mtph) | 141 ft/min (0.72 m/sec) | 46 | |

| 4,500 bph | 5,625 cu ft/hr (159.28 m3/hr) | 135 tph (122 mtph) | 159 ft/min (0.81 m/sec) | 52 | |

| 5,000 bph | 6,250 cu ft/hr (176.98 m3/hr) | 150 tph (136 mtph) | 178 ft/min (0.90 m/sec) | 58 | |

| 17 x 17 in. (432 x 438 mm) | 4,000 bph | 5,000 cu ft/hr (141.58 m3/hr) | 120 tph (109 mtph) | 98 ft/min (0.50 m/sec) | 29 |

| 5,000 bph | 6,250 cu ft/hr (176.98 m3/hr) | 150 tph (136 mtph) | 122 ft/min (0.62 m/sec) | 36 | |

| 6,000 bph | 7,500 cu ft/hr (212.38 m3/hr) | 180 tph (163 mtph) | 149 ft/min (0.76 m/sec) | 44 | |

| 7,000 bph | 8,750 cu ft/hr (247.77 m3/hr) | 210 tph (191 mtph) | 173 ft/min (0.88 m/sec) | 51 | |

| 7,500 bph | 9,375 cu ft/hr (265.47 m3/hr) | 225 tph (204 mtph) | 183 ft/min (0.93 m/sec) | 54 | |

| 21 x 17 in. (533 x 438 mm) | 7,000 bph | 8,750 cu ft/hr (247.77 m3/hr) | 210 tph (191 mtph) | 139 ft/min (0.71 m/sec) | 41 |

| 7,500 bph | 9,375 cu ft/hr (265.47 m3/hr) | 225 tph (204 mtph) | 149 ft/min (0.76 m/sec) | 44 | |

| 8,000 bph | 10,000 cu ft/hr (283.17 m3/hr) | 240 tph (218 mtph) | 159 ft/min (0.81 m/sec) | 47 | |

| 8,500 bph | 10,625 cu ft/hr (300.87 m3/hr) | 255 tph (231 mtph) | 166 ft/min (0.84 m/sec) | 49 | |

| 9,000 bph | 11,250 cu ft/hr (318.56 m3/hr) | 270 tph (245 mtph) | 176 ft/min (0.89 m/sec) | 52 | |

| 24 x 20 in. (610 x 514 mm) | 7,000 bph | 8,750 cu ft/hr (247.77 m3/hr) | 210 tph (191 mtph) | 106 ft/min (0.54 m/sec) | 21 |

| 8,000 bph | 10,000 cu ft/hr (283.17 m3/hr) | 240 tph (218 mtph) | 121 ft/min (0.61 m/sec) | 24 | |

| 9,000 bph | 11,250 cu ft/hr (318.56 m3/hr) | 270 tph (245 mtph) | 136 ft/min (0.69 m/sec) | 27 | |

| 10,000 bph | 12,500 cu ft/hr (353.96 m3/hr) | 300 tph (272 mtph) | 151 ft/min (0.77 m/sec) | 30 | |

| 12,500 bph | 15,625 cu ft/hr (442.45 m3/hr) | 375 tph (340 mtph) | 181 ft/min (0.92 m/sec) | 36 | |

| 28 x 20 in. (711 x 514 mm) | 10,000 bph | 12,500 cu ft/hr (353.96 m3/hr) | 300 tph (272 mtph) | 126 ft/min (0.64 m/sec) | 25 |

| 12,500 bph | 15,625 cu ft/hr (442.45 m3/hr) | 375 tph (340 mtph) | 161 ft/min (0.82 m/sec) | 32 | |

| 14,500 bph | 18,125 cu ft/hr (513.24 m3/hr) | 435 tph (395 mtph) | 181 ft/min (0.92 m/sec) | 36 | |

| 28 x 26 in. (711 x 667 mm) | 12,500 bph | 15,625 cu ft/hr (442.45 m3/hr) | 375 tph (340 mtph) | 119 ft/min (0.60 m/sec) | 18 |

| 15,000 bph | 18,750 cu ft/hr (530.94 m3/hr) | 450 tph (408 mtph) | 143 ft/min (0.73 m/sec) | 22 | |

| 17,500 bph | 21,875 cu ft/hr (619.43 m3/hr) | 525 tph (476 mtph) | 166 ft/min (0.84 m/sec) | 25 | |

| 32 x 26 in. (813 x 667 mm) | 15,000 bph | 18,750 cu ft/hr (530.94 m3/hr) | 450 tph (408 mtph) | 125 ft/min (0.63 m/sec) | 19 |

| 17,500 bph | 21,875 cu ft/hr (619.43 m3/hr) | 525 tph (476 mtph) | 146 ft/min (0.74 m/sec) | 22 | |

| 20,000 bph | 25,000 cu ft/hr (707.92 m3/hr) | 600 tph (544 mtph) | 166 ft/min (0.84 m/sec) | 25 |

Note

| *Capacities based on 48 lb/ft³ (768 kg/m³) material density. |

Brock Solid Drag Conveyors BR-2293-202201 (1.75MB)

Brock Solid Drag Conveyors BR-2293-202201 (1.75MB)